In the beginning, the plates were built with lead and wood, today, different materials are used that better withstand pressure, for example, photopolymers, wood, among other things. In history different materials have been used to design the types, in general a basic composition has approximately 90% lead, 6% antimony and 4% tin.

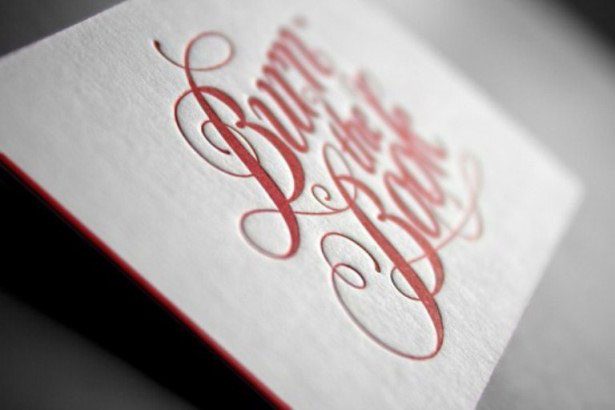

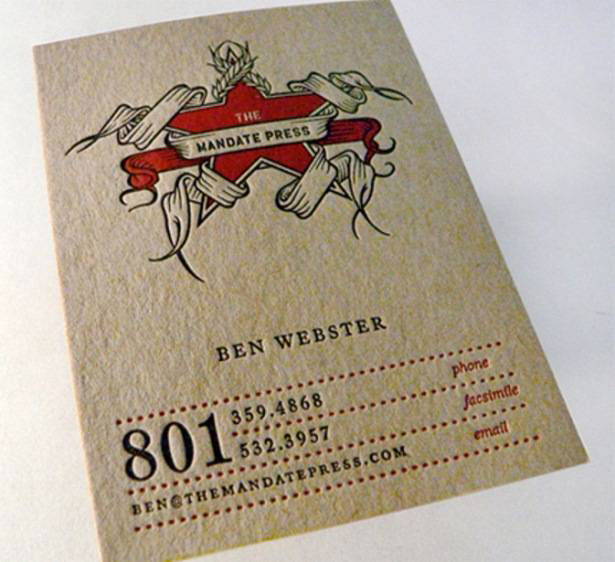

Different types of paper can be used in the letterpress process, for example, uncoated paper, cotton fiber papers, colored papers, special papers, among others. In the letterpress printing process, different materials are used for typography, below we will mention some of the most important: If you are more about graphics than words, here I share an infographic of the letterpress printing process, use it without problem I will not demand copyright if I see it out there )

It is important to clarify that (as we said before) the letterpress printing process explained above is a generalization, this means that, depending on the machine and the type of paper used, the process may vary a bit. Usually this process is carried out using a specialized spatula.ģ.The final step is precisely the letterpress printing on the selected paper, in this part of the process the ink is applied to the types of the plate and while the cylinders are rolling on the paper the image is marked on the paper (by the pressure between plate and paper generated by the cylinders). Then, as a second step we have the application of ink in the printer (specifically in the ink rollers). Then the plate should be placed in the printer in the same position as the printing rollers and the paper added.Ģ. The first step consists of preparing the letterpress printer, within this process we can recognize other threads:Assembly or composition of the plate, a process which consists of adding the types and making a subjection of them. At present it is used for author work, such as copy and card printing, as well as for alternative operations for another printing system.ĭepending on the type of letterpress machine that is being used, the printing process may vary a bit, but in general we can explain the letterpress printing process in a fairly simple way in 3 steps:ġ.The printing process can be carried out in almost any cellulosic format.The porosity and the weight of the paper are not a problem as in other printing options such as offset.Quality is not lost throughout the realization.Like any printing system, it has its benefits and problems, the case of letterpress printing is no exception, but here we share some characteristics that would definitely highlight its attributes over the other options ) Now if it is possible to better understand the concept of letterpress printing that can simply be understood as the plan to follow to make a printing on different types of paper through a somewhat complex process in which different parts of the typography system participate. Typography is known in many parts of the world as an art or a technique that consists in not only managing the letterpress printing process, but also in the selection of fonts (typefaces) so that the printing obtained is of the best quality. Definition of letterpress printingīefore knowing the definition of letterpress printing, it is important to understand the concept of letterpress. In the fifteenth century there were many problems to get information to the lower-income classes, which is why the invention of letterpress printing was so important, for the simple reason of allowing the information to reach many people at a considerable cost. Letterpress printing was invented by Johannes Gutenberg, a German who was born in 1400 and who, before his death in 1468, left our society one of the most important inventions in all of history. Letterpress printing advantages and disadvantages.

0 kommentar(er)

0 kommentar(er)